SOLUTION

Turn-key Solutions for PV Ingot Wafer Manufacturing

Solution Profile

Solution Profile

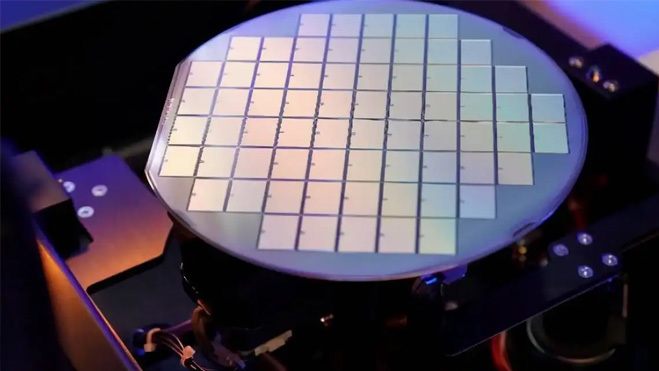

Gaoce independently develops and manufactures core equipment for the entire silicon wafer manufacturing process, including cut-off machines, squaring machines, grinding and polishing machines, and slicing machines. It also produces cutting tools such as electroplated diamond wires, loop wires, and grinding wheels, complemented by advanced cutting processes. The company’s core equipment holds over 50% global market share, with diamond wire shipments ranking among the top three in the industry. Additionally, Gaoce has established its own wafer slicing capacity, with 63GW of operational production lines and a comprehensive factory operation system covering process R&D, production management, and quality control.

Leveraging its deep technical expertise and operational experience, Gaoce provides turn-key solutions for PV ingot wafer manufacturing to global customers, offering one-stop services including factory planning and design, intelligent equipment configuration for all processes, and automated production line integration. The company’s solutions have gained high recognition worldwide, including from Adani (India’s only vertically integrated company with operational ingot pulling, slicing, cell, and module facilities), Turkey’s vertically integrated firms KalyonPV, CW Enerji, and Fellow Energy, as well as North American high-end market players Corning and Qcells. All core equipment for customers’ Phase 1 projects are supplied by Gaoce. The company also provides value-added services such as technical support, integrated control, on-site services, and training, ensuring worry-free production operations for clients.

Related Products

Related Products

GC-MK202R

GC-MJ201R-3/ GC-MJ101R-3

GC-MJ101 RW

GC-MJ706R/908R

Contact Us

Contact Us

*Note: be sure the information is filled accurately and the communication is clear, and we will get in touch with you as soon as possible

Qingdao Gaoce Technology Co., Ltd.

Tel: 86-532-87903188

Address: No. 66, Chongsheng Road, High Tech Industrial Development Zone, Qingdao, Shandong, China, 266114

Copyright © 2023 Qingdao Gaoce Technology Co., Ltd. SEO

Qingdao Gaoce Technology Co., Ltd.

Tel: 86-532-87903188

Address: No. 66, Chongsheng Road, High Tech Industrial Development Zone, Qingdao, Shandong, China, 266114

Copyright © 2022 Gaoce Technology SEO