-

Solution

Contact UsOur main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables.

Contact UsOur main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables. -

Product ShowContact UsOur main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables.

-

News

Contact UsOur main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables.

Contact UsOur main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables. -

About Us

Contact UsOur main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables.

Contact UsOur main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables. -

Contact UsOur main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables.

Contact UsOur main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables.

ABOUT US

Gaoce Inc.

To Become a World Leading Equipment & Service Provider for Hard Brittle Materials Cutting

Qingdao Gaoce Technology Co., Ltd. was established in October 2006. On August 7, 2020, it was listed on the A-share of Science and Technology Innovation Board (stock code: 688556). The headquarters of Gaoce Company is located in the High-tech Industrial Development Zone of Qingdao China with following wholly-owned subsidiaries, Changzhi Gaoce New Material Technology Co., Ltd., Huguan Gaoce New Material Technology Co., Ltd., Luoyang Gaoce Precision Machinery Co., Ltd., Leshan Gaoce New Energy Technology Co., Ltd., Yancheng Gaoce New Energy Technology Co., Ltd., and Yibin Gaoce New Energy Technology Co., Ltd.

Gaoce Company was established in October 2006.

4.474 billion yuan

Operating revenue of 4.474 billion yuan (data as of December 31, 2024)

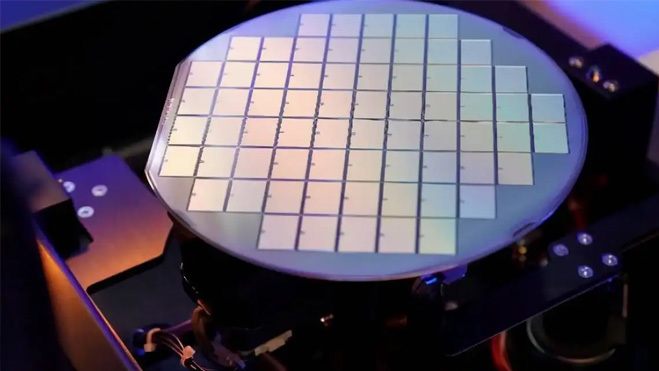

Our main business: R&D, production, sales, and supporting services for high hard brittle material cutting equipment, and cutting consumables. Based on the independent core technology, we mainly focus on providing the system solution in "cutting, squaring, grinding, and slicing" from silicon rod to silicon wafer for photovoltaic manufacturers. The top ten (10) global silicon wafer manufacturers in the PV industry are our customers.

Since 2018, we have promoted the R&D and industrial application of diamond wire cutting technology in the processing field for semiconductor silicon materials, silicon carbide materials, sapphire materials, magnetic materials, and other high hard brittle materials; we have been selected and recognized by the top-ranking enterprises in industries.

With seizing the new opportunity in quality OEM for silicon wafer, we have rapidly expanded the silicon wafer cutting service business. We regard the scientific and technical innovation as the basis, tries to continuously create value for customers, promotes cost reduction and efficiency elevation in the industry, and contributes to the goal of "carbon neutrality".

Qingdao Gaoce Technology Co., Ltd.

Tel: 86-532-87903188

Address: No. 66, Chongsheng Road, High Tech Industrial Development Zone, Qingdao, Shandong, China, 266114

Copyright © 2023 Qingdao Gaoce Technology Co., Ltd. SEO

Qingdao Gaoce Technology Co., Ltd.

Tel: 86-532-87903188

Address: No. 66, Chongsheng Road, High Tech Industrial Development Zone, Qingdao, Shandong, China, 266114

Copyright © 2022 Gaoce Technology SEO